Metal Dome User Guideline

一、Definition

1、Trip Force:The minimum force required to actuate the metal dome. Whenever the pressing force is greater than this value, metal dome start to snap downward.

2、Release Force:The minimum force required to maintain the metal dome at the stage of contact. Whenever the pressing force is lower than this value, metal dome start to spring back to original shape.

3、Free Height:Dome height without any force exerted.

4、Travel:Moving distance of contact point when metal dome actuated.

5、Click Ratio:×100% An measurable index to reflect contact "feeling"

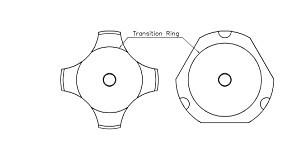

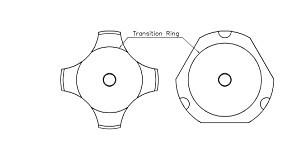

6、Collapse:The condition that the dome cannot snap back to its original shape

7、Transition Ring:A visible ring on dome surface. This is the portion that dome body transite to the dome leg, it functions as a hinge point to force the metal dome to snap back to its original shape after being pressed.

8、Contact Life:No. of effective operating cycle under certain testing criteria.

9、Dimple:For some model, there is a concaved feature located at the dome center called as "dimple".

The dimple has two function: 1) Used as an ID mark 2) Increase the contact area

10、Hole:The purpose of design of shrapnel holes in general, clients in the PCB board with LED lights, the hole casts light (Figure)

二、Measuring Guideline

1、Measuring Standard :Mainly reference to ASTM F 1597-02

2、Pre-Condition:All metal dome should be pre-conditioned 10 times with suitable force & testing perform to release the residual internal stress before taking any measurement.

3、Testing Perform:Should be flat, non-elastic and with venting slot.

4、Testing Location:Perpendicular to a region within 0.2mm of dome center

5、Force Testing Probe:Unless otherwise specified, force test probe should be hard, non-elastic pointed head.

In addition to the previously approved by the CROWNLINK(Vigatec co., Ltd.) , the other set is different from the above data

CROWNLINK(Vigatec co., Ltd.) will not agree.

三、User Guideline

1、Lot No.:The Lot no. created with the purpose to distinguish the metal domes manufacture under different conditions, such as different press, different tool, or re-setup after every tool maintenance, etc. therefore the domes come from different Lot nos. May have a slight difference in actuation/release force and dimensions, although all of them are still within the specification that specified. due to the above reason, in order to ensure the quality of your product,we do not recommend to use a mixed lot for your production. Particularly not to mix domes from different lot in one piece of assemblies.

2、Protection of Transition Ring:The function of transition ring just like a hinge, it forces the metal dome to snap back to its original shape after being pressed. Therefore, any damage on the transition ring may cause the metal dome collapse

3、Actuator:Selection of actuator size & shape should match with metal dome size in order to avoid any damage on transition ring

4、Overload:All metal dome has its designed trip force, excess pressing force may damage the dome and even cause dome collapse.

5、Over-Travel:Most of the dome are designed to use on a hard flat surface; Only a few special design according to customers' requirement, the contact point can be beneath the rest surface, except for these special design,all damage caused by over-travel.

6、Shelf Life:Because of the spring back effect and residual internal stress, trip/release force will rise gradually with time, this is why the trip/release force will different to the QC report after a period of time. We always do not recommend to store the dome for too long, and please note that we do not guarantee the quality anymore when the shelf life ended (normally 1 year)

7、Dome Quanity:Besides, In order to have a accurate conversion, sample size should associate with the resolution of the weighting instrument that used, otherwise,unexpected variation occur and thus cause unnecessary argument.

Weighting instrument resolution | Correct sample size |

0.001g | 10 pcs |

0.01g | 100 pcs |

0.1g | 1000 pcs |

1g | 10000 pcs |

Example of using incorrect sample size

Eg:CL8.4-QSN-280T Weight:0.0238g/pc Instrument resdution:0.1g Sample size:100 pcs.

Numbe\Project | actual weigh | Instrument reading |

100 pcs | 2.38g | 2.4g |

10000 pcs | 238g | 238.0g

|

Conversion result :×100%=9917pcs

Which is 83 pcs. Less than actual quanity

so, For the above example, correct sample size should be 1000 pcs.

四、Common Improper use of Metal Dome

1、Over Travel

E.g. Pressing the dome within finger tips

2、Over Load

E.g. Pressing the dome within finger tips

3、Damage of Transition Ring

E.g. rubbing on the Transition Ring with nail or hard object

4、Over sized actuator

5、Dome Legs are not evenly supported

6、INT

a) Improper assembly (e.g. Dome Legs are not evenly supported)

b)Tilt up / distortion of dome leg (eg : oversized actuator or overloaded)

c) Circuit layout not match with dome (during operation, the dome leg will slide outward slightly, circuit design should retain enough space for this movement)

7、Contact Resistance

Metal domes are made of stainless steel only, the material itself only have a very low resistance; So, when there is a high contact resistance found after assembly, it is most probably because of a poor circuit design, such as plating thickness,plating materal, trace width etc.

8、Contact Bouncing

Bouncing Contac generally occurs in the mechanical switches and relays, while the switch is generally used with the elastic metal. When the pressing spring plate and line contact, because shrapnel spring back and its impact on contact bounce, which will affect the switch system produced in contacts of electrical noise or damage itself.

Because of the design concept of metal dome,Contact bouncing can not be avoided in sometime; In order to solve the problem, the most practical way should focus on the circuit design or the device involved,for example, to add a "debounce circuit" etc.

Customer Service 3

Customer Service 3